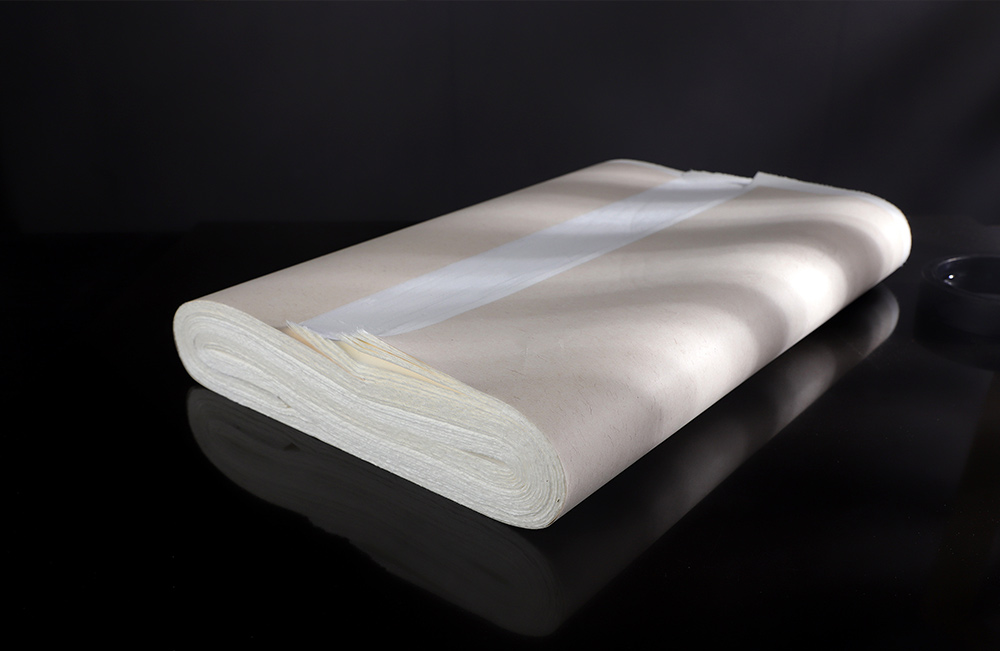

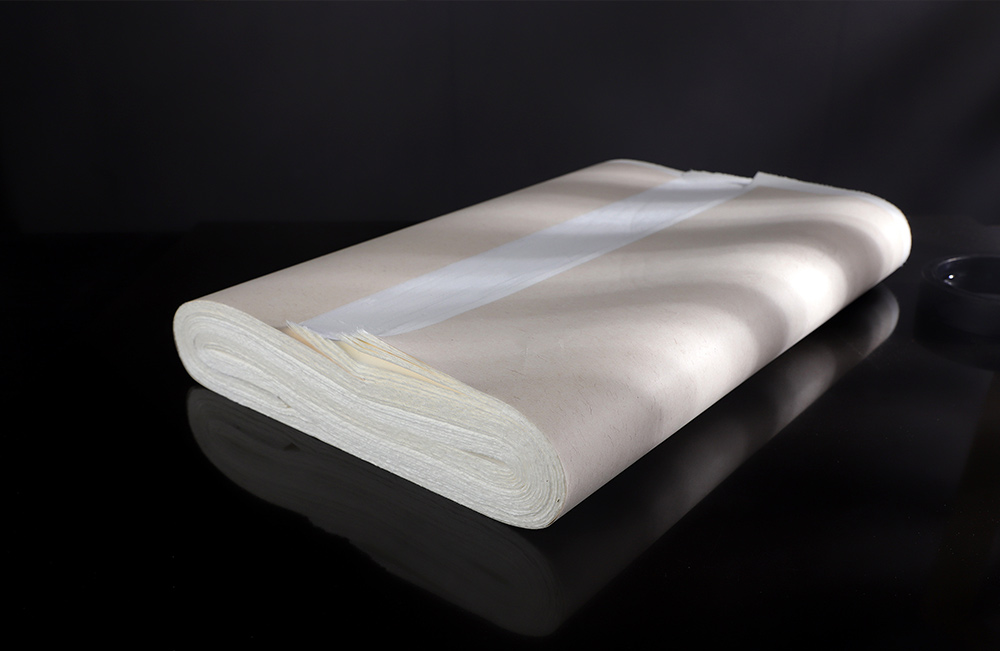

CMC products are widely used in many papermaking processes such as coating addition, in-pulp addition and surface sizing. Improve the surface strength and wear resistance of paper. In the paper industry, CMC is used in the pulping process, which can improve retention rate and increase wet strength. Used for surface sizing, as a pigment excipient, improve internal adhesion, reduce printing dust, improve printing quality; It is used for paper coating, which is conducive to the dispersion and fluidity of pigments, and enhances the finish, smoothness, optical properties and printing adaptability of paper.

The application characteristics of sodium carboxymethyl cellulose (CMC) in papermaking:

1. Improve the strength of pulp fiber, improve the strength and folding resistance of paper;

2. Enhance paper finish, smoothness, optimize printing quality;

3. Good film formation, rheology, so that the paper does not drop powder;

4. Enhance the gloss of paper surface, reduce porosity;

5. Extend the life of the scraper;