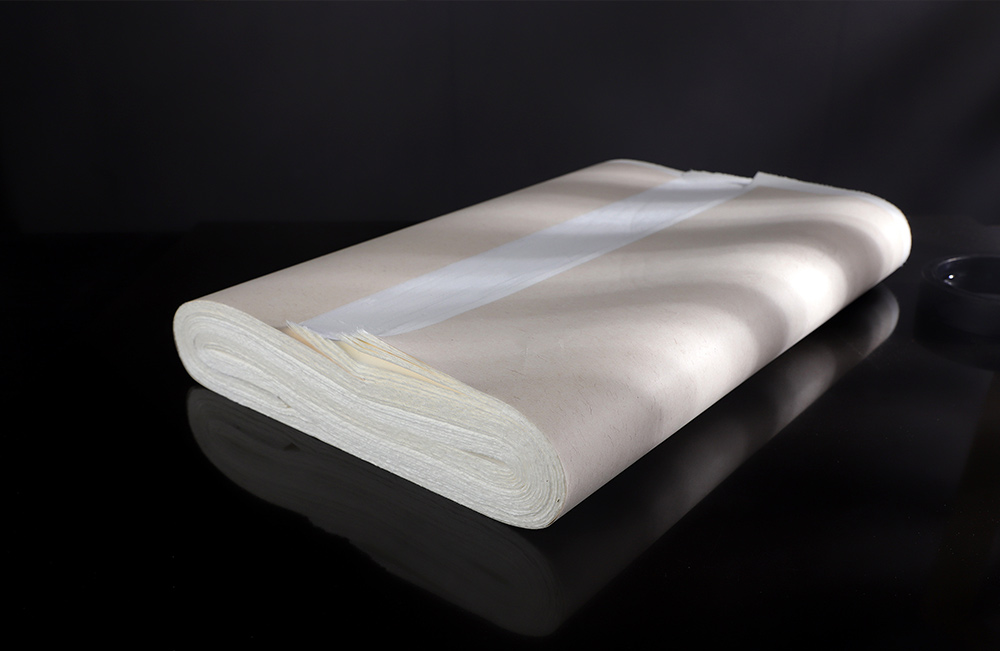

CMC is used in oil and shale gas extraction, mainly to thicken and retain water. CMC products have good salt resistance, strong antibacterial property and easy to use; The effect of reducing filtration loss and increasing viscosity is good, and the rheological control and suspension ability are strong.

The application characteristics of sodium carboxymethyl cellulose (CMC) in oilfield:

1. The slurry can effectively inhibit the dispersion of clay and reduce its pulping speed, thus controlling the pollution of the well wall and strengthening the well wall;

2. Excellent temperature and salt resistance, excellent filtration loss reduction, reducing free water. Under a certain salt concentration, it can still have a good ability to reduce water loss and a certain rheology, and adjust the rheology of drilling fluid.

3. CMC products are green, non-toxic, harmless and odorless; Good product fluidity, convenient construction.